With THINKY mixers, you can homogeneously mix and degas:

Liquids

Pastes

Powders

Fillers

Engineering and pharmaceutical materials

Non-contact ‘planetary’ mixing

By means of the rotation and revolution ‘planetary’ mixing principle, without the use of blades, paddles or other invasive tools, even high viscosity materials and nano-particles can be effectively mixed, dispersed and degassed with minimal stress on the materials themselves.

No Clean-Up: The planetary centrifugal motion of the mixer means that you can mix in standard THINKY jars or your own containers such as beakers, syringe tubes or cartridges without any mixing implements to clean between batches.

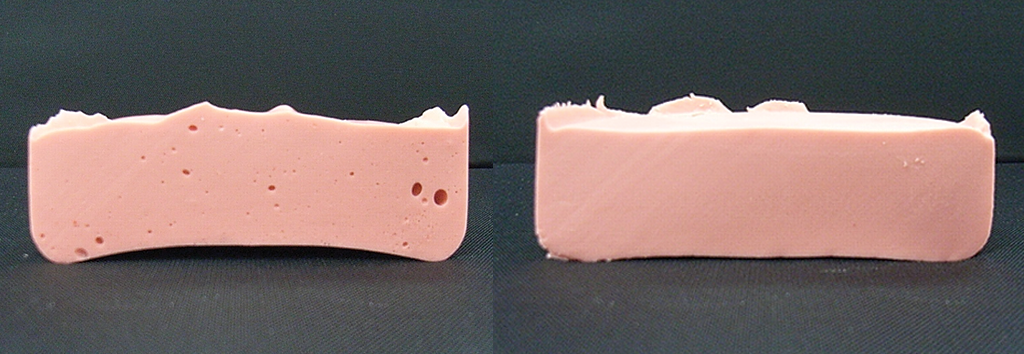

Bubble-Free: The process naturally degasses compounds, but if micro-bubbles are a concern, several THINKY mixer models feature a vacuum mode to go the extra mile in removing any trapped air.

See the results some of our customers have achieved:

A batch size can be anything from 0.5ml to 20L depending on the size of your THINKY machine.

THINKY mixers start at around £5,000, and you can see a speedy return on investment when you consider the time required to manually mix and clean implements, plus you benefit from the knowledge that your materials are thoroughly and consistently mixed. Have a look at our range of THINKY models:

|

Get to know the THINKY mixer rangeRead our handy introduction to discover how THINKY mixers process your materials to achieve a homogeneous mix in seconds to minutes. |

|

Vacuum mixing and degassingFor specific applications that require a material to contain no micro-bubbles, a mixing and vacuum degassing machine is the efficient choice as illustrated in this THINKY model comparison.

|

|

How to choose a THINKY mixerChoosing the correct mixer with the right capabilities for a process will often depend on the materials you need to mix and the results you are after. This technical bulletin highlights the key considerations for selecting a suitable planetary mixer for your application. |