THINKY ARE-312 Mixing and Degassing Machine, Conditioning Planetary Mixer

THI ARE-312

About THINKY ARE-312 Mixing and Degassing Machine, Conditioning Planetary Mixer

The THINKY ARE-312 mixing and degassing machine is an industrial non-contact “planetary” mixer for all engineering compounds – liquids, pastes and powders. Using a non-contact mixing principle it mixes, disperses and degases up to 310g of your material in seconds to minutes in sealed or lid-less containers. Using this mixing method the machine is capable of formulating compounds in amounts from 0.5g.

The THINKY ARE-312 is an updated version of our very successful and popular flagship mixer the THINKY ARE-250, which has 100’s of UK installations. The ARE-312 has many improvements, but in particular, it features:

- Faster mixing and defoaming power with a new high torque, low temperature motor

- PC connectivity via RS232 for control, monitoring, traceability, and programming

- 20 memory “recipe” slots with 10 program steps in each slot

The THINKY ARE-312 Mixer enables a mixing and bubble removal processes to occur concurrently. Functioning as a conditioning mixer, it accommodates various substances such as epoxies, silicones, conductive pastes, pharmaceuticals, cosmetics, and many other chemical materials, facilitating efficient mixing and/or bubble removal.

With its Multi-Step Mixing capability, you can set up to ten distinct mixing and degassing recipes (time and speed per mode) within one batch cycle. This precise process control not only enhances formulation quality but also minimises human errors or operator dependencies. Additionally, the mixer features built-in data logging through PC connectivity, offering precise data outputs including mixer RPM, selected mixing mode and active recipe information.

Cooled or heated materials can be processed with special adapters. The ARE-312 can accept syringes up to 55ml or up to 75ml (2.5oz) cartridges with optional adapters. THINKY mixers with vacuum capability and larger mixers are also available.

Improved motor

The updated motor in the ARE-312 gives improved mixing and defoaming/degassing power. With speeds up to 2200rpm for mixing and 2400rpm for degassing, faster mixes are possible. Capabilities for high-speed mixing are enhanced, even with highly filled/high mass materials, and the internal temperature rise is suppressed.

Computer connection

Via the RS232 port, using the included software, the ARE-312 has these functions:

- Programming

“Recipes” can be edited on a connected computer. Recipe files are exported to/imported from the ARE-312. A recipe lock function is available. - Controlling

Remote control and start/stop operation. Traceability functions include reports on operating status, error history and operating history. - Monitoring

In conjunction with the THINKY Multi-Sensor, monitoring and recording of temperature, rotation speed and revolution speed.

Safety

In addition to the standard revolution, vibration and door sensors, the ARE-312 has an impact sensor. The lid now has two latches for added security.

Features & Benefits

- For low, medium and high viscosity materials with various densities as well as powders

- Simultaneous homogeneous dispersion and degassing in one batch

- Process in seconds to minutes

- Mix in your containers such as jars, barrels, cartridges, syringes or tubes

- Remove voids and re-disperses filled materials packed in syringes

- Non-invasive, bladeless processing ends the risk of cross contamination between batches

- Process from 0.5ml – save valuable material and reduce wastage

- Re-mixing of separated materials to prolong shelf life

- Vacuum-less processing, degassing and de-aeration

- No damage to material unlike with the use of rollers, mixing blades or propellers

- No unit cleaning between batches eliminates non-productive work

Applications

The THINKY ARE-312 can be used to formulate and mix adhesives, sealants, moulding compounds, lubricants, slurries, coatings, inks, paints, abrasives, bio chemicals, cements, medical compounds, cosmetics/personal care materials, detergents, conductive pastes, dental materials, foods, construction materials, battery slurry and electrode slurries, or any other materials which are hard to mix, hard to degas, or hard to wet. These include mixing powders and particles (including nanoparticles) into liquids and pastes.

Here are some examples of applications for the THINKY ARE-312:

| Epoxy resin |  |

| Epoxy resin, hardener and aluminium powder are mixed in 6.5 minutes. Ingredients are dispersed evenly. | |

| Solder Paste |  |

| Creamy solder paste with no air bubbles is made from solder powder and flux. Processed with ARE-250 in 45 seconds. | |

| Cosmetics |  |

| Ingredients for face cake, wax and coloured iron oxide, are mixed completely with the ARE-250 in 5 minutes. | |

| Ointment |  |

| Mixing yellow pigment into zinc oxide without solvent. It dispersed homogeneously with the ARE-250 in 20 seconds. |

Specifications

| Specification | |

|---|---|

| Minimum material capacity | 0.5g |

| Maximum mixing volume | 300ml container: 250ml / 250g (310g gross) |

| Timer | Set up to 30 minutes, 1 second increments |

| Programming | Mixing and/or degassing mode, multi-step mixing, speed changer |

| Memory | 10 memory slots are available for different 20 batch cycles. Programmed mixing procedure can be recalled in a second. |

| External communication | RS232 serial port |

| Safety features | Lid sensor, vibration sensor, impact sensor, CE marked |

| Operating environment | 10 to 35 ℃, 35 to 85 % RH(without condensation) |

| Weight | 21kg |

| Dimensions (mm) | H390 X W300 X D300mm |

| Power requirements | 230V +/- 10% 50Hz |

Other Information

See how THINKY mixers work as part of real applications in these metering and mixing Case Studies:

|

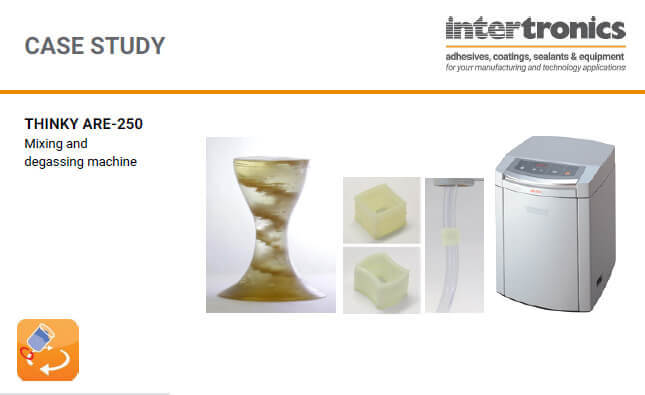

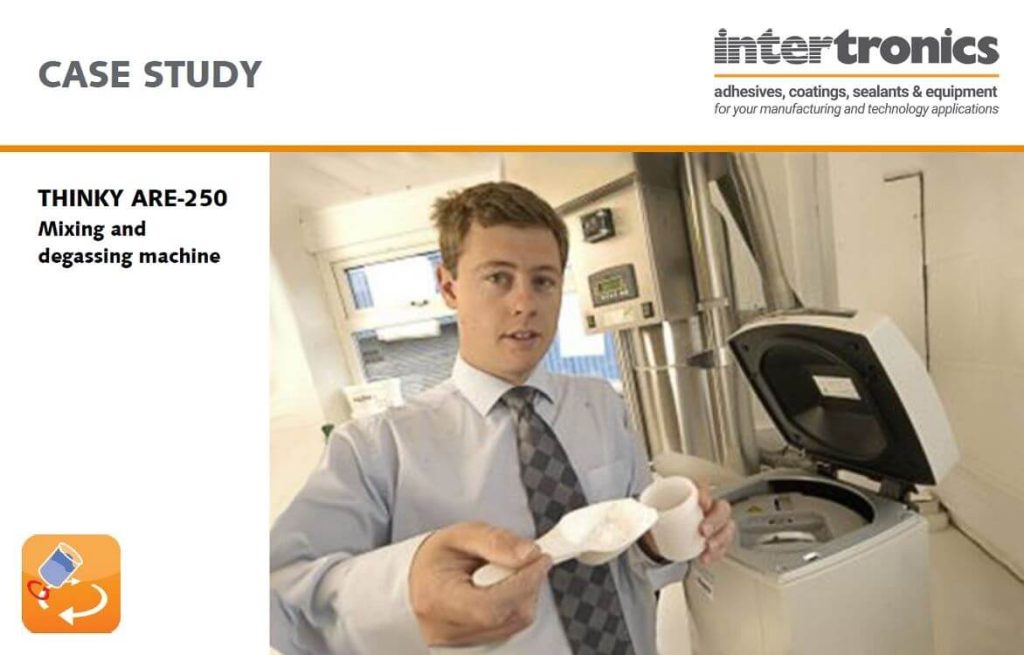

THINKY ARE-250 mixes 3D printing materials homogeneously

A team of material scientists at ETH Zurich University have been developing new materials for 3D printing which deliver additional functionality. To ensure that the source material mixes homogeneously with the fillers, they use the THINKY ARE-250 mixer. |

|

Effective mixing of specialist glass powders with a high viscosity acrylic resin

Consistent high quality mixing and improved degassing of powders into resins advanced the process capabilities of a ceramic materials company. |

|

Getting to know THINKY Mixers Download a presentation which describes how THINKY Mixers work, and what benefits they can deliver to you. |

Ordering Information

| Part number | Description | |

|---|---|---|

| THIARE-312 | Thinky Mixer ARE-312 Includes 3 x THI300ML 300ml jars, 1 x THI150ML 150ml jar and 1 x THI250AD-201 adapter, software |

|

| Containers | Adapter | |

| THI300ML | 300ml HDPE thick wall jar with inner lid & cap – re-usable | None |

| THI150ML | 150ml HDPE thick wall jar with inner lid & cap – re-usable | THI250AD-201 |

| THI240ML | 240ml Polypropylene jar and screw cap | THI250AD-8OZ |

| Container adapters | ||

| THI250AD-3S | Adapter for EFD-type 3ml syringe | |

| THI250AD-5S | Adapter for EFD-type 5ml syringe | |

| THI250AD-10S | Adapter for EFD-type 10ml syringe | |

| THI250AD-30S | Adapter for EFD-type 30ml syringe | |

| THI250AD-50S | Adapter for EFD-type 55ml syringe | |

| THI250AD-201 | Adapter for THI150ML HDPE container | |

| THI250AD-8OZ | Adapter for THI240ML Polypropylene container | |

| THI250AD-2.5S | Adapter for 2.5oz (~75ml) cartridge | |

We have many other containers of different sizes, as well as as adapters for cool or hot mixing. Custom adapters are available for your own unique containers.

Let’s start by talking about your application

- Last updated: May 2024

- Version: 1.0

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.